Reduce Time and Costs With Readily Available Essential Pneumatic Components

Using preconfigured, readily available pneumatic components — what we call “essential” products — are key to mitigating supply chain risks, improving maintenance efficiency and reducing commissioning time. Not only are these products stocked and ready to ship, they’re also technically innovative, incorporating unique features that save space, simplify installation and reduce your overhead costs.

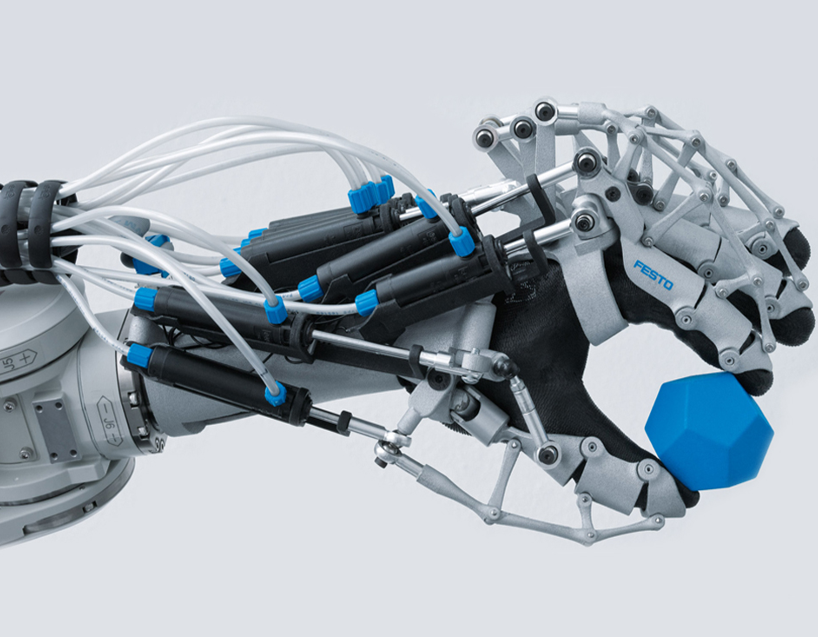

Here’s a rundown of the essential components that play a role in pneumatic applications, as well as the benefits you can expect when you source these products from Festo.

What Are the Essential Products in a Pneumatic System?

Essential components play a role in all pneumatic applications, to some degree, and include the following:

Air preparation units, which filter the compressed air at the correct, preconfigured pressure in order to operate pneumatic equipment at optimal performance levels.

Tubing, typically polyurethane.

Valves to control the airflow that operates the cylinders.

Flow controls, which manage the speed of the cylinder piston.

Cylinders, the most common of which are round body cylinders, NFPA-style cylinders, guided drives and mini slides.

Cylinder switches, such as proximity sensors, which detect the piston’s position.

Despite the fact that these products are the most basic components that make up a pneumatic system, they still incorporate technically innovative features. For example, the DGST mini slide is the most compact slide actuator on the market. Its design, which brings the shock absorbers inside the frame of the body, saves space, reduces moment loads and increases the unit’s load capacity. In addition, the slide and yoke are machined out of one piece, providing high levels of perpendicularity.

Another technically innovative essential product is the SDBT proximity sensor, the first to feature an auto-teach function that simplifies the installation process. And, with its detection range of 20 millimeters, units are safe and easy to install — especially when mounting is more difficult.

The Benefits of Going Essential

Using preconfigured, readily available components unlocks many benefits, from mitigating supply chain risks to enabling fast, efficient maintenance. In addition:

Readily available components help machine builders ship finished machines more quickly, reducing time to market.

Preconfigured products reduce engineering time and the associated costs.

Easy-to-deploy components reduce commissioning time and costs.

The products themselves are attractively priced, thanks to their optimized designs by the Festo engineering team.