How Pneumatic Cylinder Work? Described Instructions

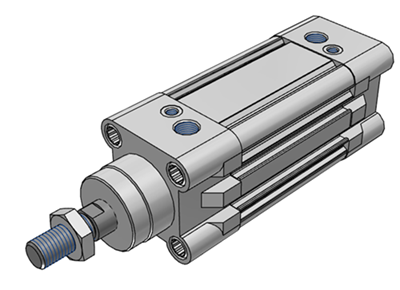

The pneumatic cylinder is a device that has been mechanically engineered to produce force (in linear motion) from compressed gas. They are also known as air cylinders.

The air cylinders come in various appearances and sizes and are meant to perform different functions depending on the rising needs of the market. Depending on your ready market, you can choose to go for

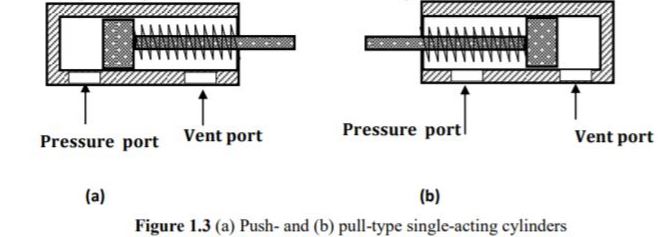

1) Single-acting Cylinder

This type of air cylinder is quite small in size as compared to the other types. They create driving linear force from the pressure imparted by the compressed air by the piston which then springs back to the original position. This type of air cylinder will be best suitable for the customers who need little application since it has a limited extension due to the small space for compressed air.

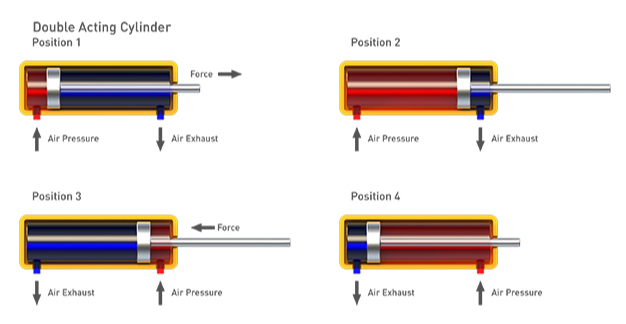

2) Double acting cylinders

With expanded application, a customer can consider buying this machine. It has two ports that enable it to perform both extend and retract strokes. Its stroke length is also not limited a fact that presents the double acting cylinder a better choice of pneumatic cylinder that should never miss in your hardware shop stock.

3) Multiple stage telescoping cylinder

As the name suggests, it is a combination of both sing-acting cylinder and the double acting cylinder in performance capability. With both piston rod nested with series of hollow stages in an increasing diameters; this machine allows notable longer strokes.

lt is the best tool for customers who deal with applications that have minimal side loading.These are the main types of air cylinders that are well known and widely used whose demands suit the market. However, there are other types too.Why should you stock the pneumatic cylinders?

The air cylinders work with the basic physics principles which state that force produced by the cylinder is directly proportional to the surface area of the piston acting on it with other factors like the friction and the turbulence kept constant. This theoretically implies that the machine performs reliably between 50% and 70%.

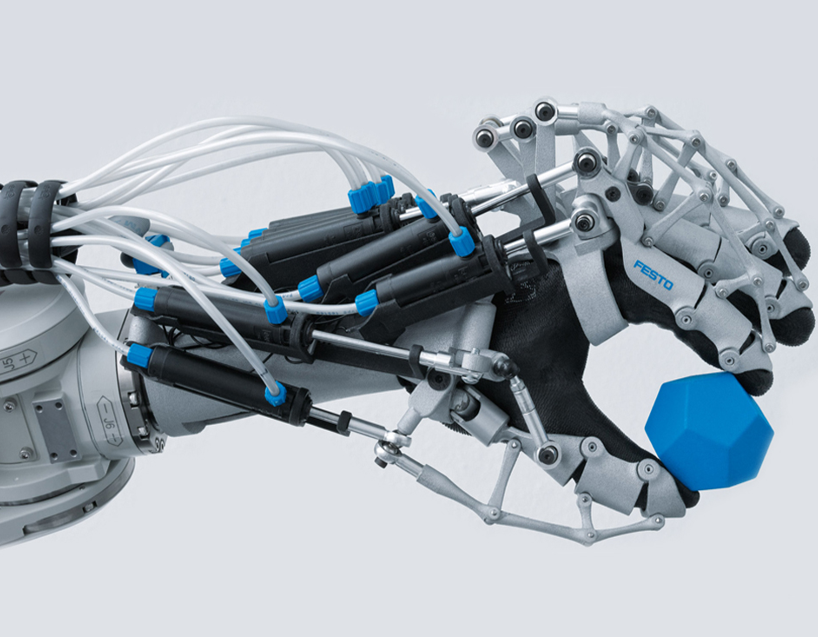

Their extensive usage makes them more marketable since. Many engineers choose to use the pneumatic cylinder since they are cleaner, produce less noise,and they do not need large space for fluid storage.

In addition, pneumatic cylinders are also the most preferred in the market since their operating fluid is a gas; and by the fact that gases do not drip during leakages keeps the operating environment cleaner.

The air cylinders are also worthy in the stock since their choice of use is wider depending on the job specification, the level of loads, temperature, and stroke length needed.

Air cylinder installed with quick exhaust valves increases the air cylinder cycle. This makes your stock more marketable and allows quick replenishing of stock as these will be the most preferred machines.

When going to shop for the pneumatic cylinders, customer is often driven by the quality of the product. As an entrepreneur of air cylinders, you need to win the trust of your customer by stocking standard air cylinders that have a wide range of bone sizes of 16 and 18 inches of bore sizes and metric sizes respectively.

The cylinders must also have many mounting configuration and standard switch capability that relies on the location of the application and mach-inability of the air cylinder.

For the double-acting pneumatic cylinders with two pressure setup, you can consider stocking the types with air pressure and exhaust valve installed which during operation leads to a higher pressure production for the work force and low pressure for return force.

This modification systematically reduces the operational cost; features that have made air cylinders more marketable as such are the machines that can be multipurpose. When operating with the pneumatic cylinder, customers are often pissed up by the noise it produces from the impacting air cylinder end caps.

The noise is not only irritating to the user but also harmful to the machine itself and this could be a turnoff to the operators. Therefore to make small but significant changes to your models in stock will be to your business’ advantage. You can either add to your stock the internal cushions or customize your appliances by fixing the cushions that will add to the stroke time and reduce noise produced by the stocked air cylinders.

Cushions are always adjustable hence are less expensive. This will significantly increase the demand from your customers as well as making the air cylinder more suitable for use even to customers in noise-restricted areas.

In your stocking, you can also consider having a continuous feedback sensor and closed-loop valve controller incorporated air cylinders in stock thus making them both fully extended and fully retracted. These machines will effectively provide linear electric drives a quality looked for in the market.

The features air cylinders definitely present uniqueness an increased demand for your machines that will make them highly competitive in the market.